Discover Harmony

The Harmony Way

Initial Plan Review

Important project plan elements are discussed, including:

Wood species – Joinery styles

Frame complexity – Decorative elements

Then, Harmony project estimators review the plans to determine the project scope and estimated costs.

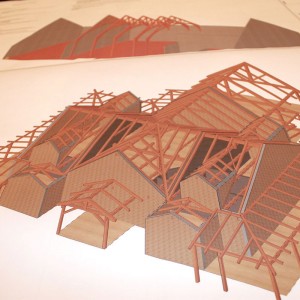

3-Dimensional Modeling

Once the proposal is approved, the designers will produce a 3-Dimensional model of the structure. This gives you, your architect and builder the ability to view the timber frame from different vantage points and see how it will integrate with your building plans.

Timber Frame System Design

After the 3-D model is approved, our design team will develop the entire timber frame system including individual joinery details for all frame sections. Final design sign-off and frame engineering review are completed at this point.

Timber Cutting

Next we’ll craft the individual timber joinery, using a combination of modern CNC timber cutting technology and the old-world hand cutting methods of the Harmony joiners and master craftsmen.

Test Fitting

Test fitting ensures accuracy and quality standards of all joints and timber pieces are met prior to on-site installation. Timbers are then identified and tagged to identify their position in the timber frame layout.

Delivery and Installation

Harmony Timberworks is committed to meeting the timetables established during the planning stages of production. However, we understand that unavoidable circumstances and on site delays can impact your schedule, which is why our project management team will communicate and coordinate with you to ensure your timber system arrives exactly when you need it.